Young Researcher Paper Award 2025

🥇Winners

🥇Winners

Print: ISSN 0914-4935

Online: ISSN 2435-0869

Sensors and Materials

is an international peer-reviewed open access journal to provide a forum for researchers working in multidisciplinary fields of sensing technology.

Online: ISSN 2435-0869

Sensors and Materials

is an international peer-reviewed open access journal to provide a forum for researchers working in multidisciplinary fields of sensing technology.

Tweets by Journal_SandM

Sensors and Materials

is covered by Science Citation Index Expanded (Clarivate Analytics), Scopus (Elsevier), and other databases.

Instructions to authors

English 日本語

Instructions for manuscript preparation

English 日本語

Template

English

Publisher

MYU K.K.

Sensors and Materials

1-23-3-303 Sendagi,

Bunkyo-ku, Tokyo 113-0022, Japan

Tel: 81-3-3827-8549

Fax: 81-3-3827-8547

MYU Research, a scientific publisher, seeks a native English-speaking proofreader with a scientific background. B.Sc. or higher degree is desirable. In-office position; work hours negotiable. Call 03-3827-8549 for further information.

MYU Research

(proofreading and recording)

MYU K.K.

(translation service)

The Art of Writing Scientific Papers

(How to write scientific papers)

(Japanese Only)

is covered by Science Citation Index Expanded (Clarivate Analytics), Scopus (Elsevier), and other databases.

Instructions to authors

English 日本語

Instructions for manuscript preparation

English 日本語

Template

English

Publisher

MYU K.K.

Sensors and Materials

1-23-3-303 Sendagi,

Bunkyo-ku, Tokyo 113-0022, Japan

Tel: 81-3-3827-8549

Fax: 81-3-3827-8547

MYU Research, a scientific publisher, seeks a native English-speaking proofreader with a scientific background. B.Sc. or higher degree is desirable. In-office position; work hours negotiable. Call 03-3827-8549 for further information.

MYU Research

(proofreading and recording)

MYU K.K.

(translation service)

The Art of Writing Scientific Papers

(How to write scientific papers)

(Japanese Only)

Sensors and Materials, Volume 37, Number 10(2) (2025)

Copyright(C) MYU K.K.

Copyright(C) MYU K.K.

|

pp. 4447-4458

S&M4193 Research Paper https://doi.org/10.18494/SAM5844 Published: October 21, 2025 Geometric-overlap Modeling and Sweep Uniformity Optimization of Fixed Diamond Conditioning Disks for Chemical Mechanical Planarization [PDF] Yu-Chen Wang, Hong-Hui Lian, Yue-Feng Lin, and Ming-Yi Tsai (Received July 14, 2025; Accepted October 9, 2025) Keywords: CMP, diamond conditioning disk, polishing pad dressing uniformity, geometric-overlap model

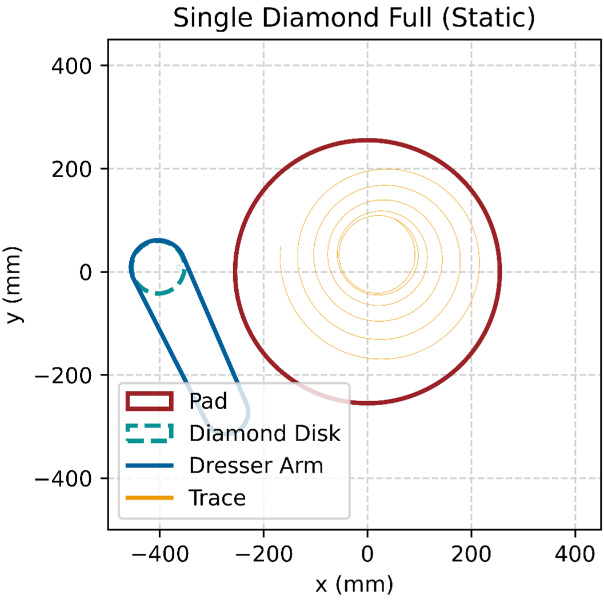

In this study, we develop a graphics processing unit (GPU)-accelerated geometric-overlap model for fixed-abrasive diamond conditioning disks used in chemical mechanical planarization (CMP). The framework systematically evaluates how diamond-layout strategies and arm-sweep kinematics affect polishing pad coverage uniformity and overall economic performance. A planar rigid-body motion model is first established for diamond chips under the coupled action of disk self-rotation and arm oscillation, and a unified metric, the normalized overlap area ratio (NAR), is defined to quantify radial-sweep uniformity. Simulation conditions are assumed to be a pad diameter of 510 mm, an arm amplitude of ±34°, and a disk speed of 87 rpm; diamond counts from three to twelve are assessed. Trajectory superposition and hit-density statistics are accelerated on a GPU using CuPy. Results show that a single diamond traces an Archimedean-like spiral, mitigating local wear gradients and impact concentration. With seven to eight diamonds, phase-complementary effects fill the central sweep dead zone, raising NAR to ≈30% and optimizing radial and angular uniformities. Integrated cost-performance analysis indicates that a seven- or eight-diamond configuration provides the best trade-off between coverage efficiency and diamond usage; counts above eight lead to excessive overlap in the central region and uneven inner–outer distributions, shortening pad life and raising manufacturing costs, thus driving the system into diminishing returns. The proposed model supplies quantitative guidelines for CMP dresser design, delivering practical benefits for process stability and cost efficiency. These are critical for manufacturing high-performance sensors and devices on advanced material substrates.

Corresponding author: Ming-Yi Tsai  This work is licensed under a Creative Commons Attribution 4.0 International License. Cite this article Yu-Chen Wang, Hong-Hui Lian, Yue-Feng Lin, and Ming-Yi Tsai, Geometric-overlap Modeling and Sweep Uniformity Optimization of Fixed Diamond Conditioning Disks for Chemical Mechanical Planarization, Sens. Mater., Vol. 37, No. 10, 2025, p. 4447-4458. |

Forthcoming Regular Issues

Forthcoming Special Issues

Special Issue on Novel Sensors, Materials, and Related Technologies on Artificial Intelligence of Things Applications

Guest editor, Teen-Hang Meen (National Formosa University), Wenbing Zhao (Cleveland State University), and Cheng-Fu Yang (National University of Kaohsiung)

Call for paper

Special Issue on Unique Physical Behavior at the Nano to Atomic Scales

Guest editor, Takahiro Namazu (Kyoto University of Advanced Science)

Call for paper

Special Issue on Support Systems for Human Environment Utilizing Sensor Technology and Image Processing Including AI

Guest editor, Takashi Oyabu (Nihonkai International Exchange Center)

Call for paper

Special Issue on Mobile Computing and Ubiquitous Networking for Smart Society

Guest editor, Akira Uchiyama (The University of Osaka) and Jaehoon Paul Jeong (Sungkyunkwan University)

Call for paper

Special Issue on Advanced Materials and Technologies for Sensor and Artificial- Intelligence-of-Things Applications (Selected Papers from ICASI 2026)

Guest editor, Sheng-Joue Young (National United University)

Conference website

Call for paper

Special Issue on Innovations in Multimodal Sensing for Intelligent Devices, Systems, and Applications

Guest editor, Jiahui Yu (Research scientist, Zhejiang University), Kairu Li (Professor, Shenyang University of Technology), Yinfeng Fang (Professor, Hangzhou Dianzi University), Chin Wei Hong (Professor, Tokyo Metropolitan University), Zhiqiang Zhang (Professor, University of Leeds)

Call for paper

-

For more information of Special Issues (click here)

-

Special Issue on Signal Collection, Processing, and System Integration in Automation Applications

- Accepted papers (click here)

- High-precision Autonomous Driving Map Quality Inspection Indicator System and Evaluation Method

Chengcheng Li, Ming Dong, Hongli Li, Xunwen Yu, Yongxuan Liu, and Chong Zhang

- High-precision Autonomous Driving Map Quality Inspection Indicator System and Evaluation Method

- Accepted papers (click here)

- Scalable Real-time Energy Monitoring, Analysis, and Optimization in Five-axis Machine Tools: An Industrial Internet of Energy-based Approach

Swami Nath Maurya, Kun-Ying Li, Windu Aditya Nur Faeza, and Yue-Feng Lin

- Scalable Real-time Energy Monitoring, Analysis, and Optimization in Five-axis Machine Tools: An Industrial Internet of Energy-based Approach

Guest editor, Hsiung-Cheng Lin (National Chin-Yi University of Technology)

Call for paper

Special Issue on Advanced Materials and Technologies for Sensor and Artificial- Intelligence-of-Things Applications (Selected Papers from ICASI 2025)

Guest editor, Sheng-Joue Young (National United University)

Conference website

Call for paper

Special Issue on Multisource Sensors for Geographic Spatiotemporal Analysis and Social Sensing Technology Part 5

Guest editor, Prof. Bogang Yang (Beijing Institute of Surveying and Mapping) and Prof. Xiang Lei Liu (Beijing University of Civil Engineering and Architecture)

Special Issue on Advanced GeoAI for Smart Cities: Novel Data Modeling with Multi-source Sensor Data

Guest editor, Prof. Changfeng Jing (China University of Geosciences Beijing)

Call for paper

Special Issue on Materials, Devices, Circuits, and Analytical Methods for Various Sensors (Selected Papers from ICSEVEN 2025)

Guest editor, Chien-Jung Huang (National University of Kaohsiung), Mu-Chun Wang (Minghsin University of Science and Technology), Shih-Hung Lin (Chung Shan Medical University), Ja-Hao Chen (Feng Chia University)

Conference website

Call for paper

Special Issue on Sensing and Data Analysis Technologies for Living Environment, Health Care, Production Management, and Engineering/Science Education Applications (2025)

Guest editor, Chien-Jung Huang (National University of Kaohsiung), Rey-Chue Hwang (I-Shou University), Ja-Hao Chen (Feng Chia University), Ba-Son Nguyen (Lac Hong University)

Call for paper

Special Issue on Advances in Sensors and Computational Intelligence for Industrial Applications

Guest editor, Chih-Hsien Hsia (National Ilan University)

Call for paper

Special Issue on AI-driven Sustainable Sensor Materials, Processes, and Circular Economy Applications

Guest editor, Shih-Chen Shi (National Cheng Kung University) and Tao-Hsing Chen (National Kaohsiung University of Science and Technology)

Call for paper

- Accepted papers (click here)

Copyright(C) MYU K.K. All Rights Reserved.