Young Researcher Paper Award 2025

🥇Winners

🥇Winners

Print: ISSN 0914-4935

Online: ISSN 2435-0869

Sensors and Materials

is an international peer-reviewed open access journal to provide a forum for researchers working in multidisciplinary fields of sensing technology.

Online: ISSN 2435-0869

Sensors and Materials

is an international peer-reviewed open access journal to provide a forum for researchers working in multidisciplinary fields of sensing technology.

Tweets by Journal_SandM

Sensors and Materials

is covered by Science Citation Index Expanded (Clarivate Analytics), Scopus (Elsevier), and other databases.

Instructions to authors

English 日本語

Instructions for manuscript preparation

English 日本語

Template

English

Publisher

MYU K.K.

Sensors and Materials

1-23-3-303 Sendagi,

Bunkyo-ku, Tokyo 113-0022, Japan

Tel: 81-3-3827-8549

Fax: 81-3-3827-8547

MYU Research, a scientific publisher, seeks a native English-speaking proofreader with a scientific background. B.Sc. or higher degree is desirable. In-office position; work hours negotiable. Call 03-3827-8549 for further information.

MYU Research

(proofreading and recording)

MYU K.K.

(translation service)

The Art of Writing Scientific Papers

(How to write scientific papers)

(Japanese Only)

is covered by Science Citation Index Expanded (Clarivate Analytics), Scopus (Elsevier), and other databases.

Instructions to authors

English 日本語

Instructions for manuscript preparation

English 日本語

Template

English

Publisher

MYU K.K.

Sensors and Materials

1-23-3-303 Sendagi,

Bunkyo-ku, Tokyo 113-0022, Japan

Tel: 81-3-3827-8549

Fax: 81-3-3827-8547

MYU Research, a scientific publisher, seeks a native English-speaking proofreader with a scientific background. B.Sc. or higher degree is desirable. In-office position; work hours negotiable. Call 03-3827-8549 for further information.

MYU Research

(proofreading and recording)

MYU K.K.

(translation service)

The Art of Writing Scientific Papers

(How to write scientific papers)

(Japanese Only)

Sensors and Materials, Volume 36, Number 10(1) (2024)

Copyright(C) MYU K.K.

Copyright(C) MYU K.K.

|

pp. 4221-4238

S&M3796 Research Paper of Special Issue https://doi.org/10.18494/SAM5110 Published: October 11, 2024 Real-time Thermal Error Compensation of Machine Tools Based on Machine Learning Model and Actual Cutting Measurement via Temperature Sensors [PDF] Gang Chen and Kun-Chieh Wang (Received April 30, 2024; Accepted September 17, 2024) Keywords: thermal error, thermal error compensation, CNC machine tools, real-time measurement

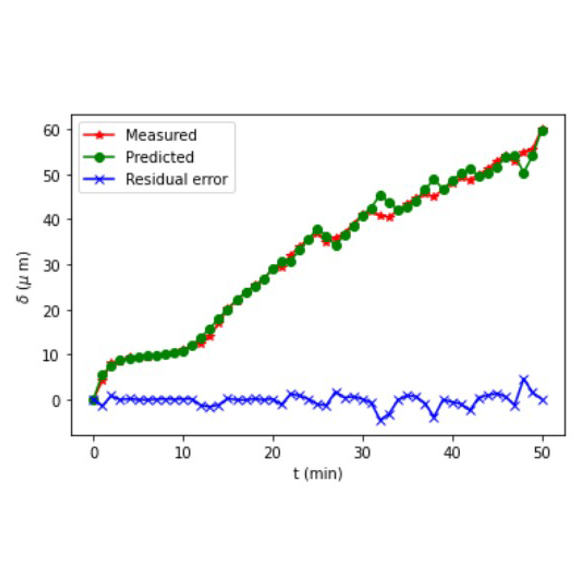

In computer-numerical-controlled (CNC) machine tools, factors affecting machining precision mainly stem from the machine’s own geometric errors and errors occurring during cutting due to thermal effects on its structure. Typically, thermal errors contribute to more than 70% of the total error. Hence, minimizing thermal errors in CNC machine tools is highly regarded. One significant and commonly used approach is the thermal error compensation (TEC) method. Although the TEC method has been extensively applied in both laboratory and industrial CNC machines, several challenges remain. For instance, the determination of optimal temperature characteristic points for various CNC machine tools requires improved methods, the mathematical models for predicting and compensating thermal errors are not sufficiently accurate, and there is poor compensation performance under varying cutting conditions. In this research, we focus on thermal error prediction and compensation technology for a CNC high-speed four-rail vertical machining center. Through actual cutting experiments, we measure temperatures at feature points on the machine and spindle deformation using various high-tech sensors. Subsequently, precise prediction and rapid compensation models for thermal errors are established using support vector regression and transfer function matrix methods, respectively. Finally, a TEC system based on a single-chip microprocessor is developed. In this system, we perform real-time TEC during actual machining by adjusting the machine’s original point drift. Results from actual cutting experiments demonstrate that the developed TEC system can effectively reduce the target machine’s thermal deformation from 110 µm to within 10 µm in real time.

Corresponding author: Kun-Chieh Wang  This work is licensed under a Creative Commons Attribution 4.0 International License. Cite this article Gang Chen and Kun-Chieh Wang, Real-time Thermal Error Compensation of Machine Tools Based on Machine Learning Model and Actual Cutting Measurement via Temperature Sensors, Sens. Mater., Vol. 36, No. 10, 2024, p. 4221-4238. |

Forthcoming Regular Issues

Forthcoming Special Issues

Special Issue on Novel Sensors, Materials, and Related Technologies on Artificial Intelligence of Things Applications

Guest editor, Teen-Hang Meen (National Formosa University), Wenbing Zhao (Cleveland State University), and Cheng-Fu Yang (National University of Kaohsiung)

Call for paper

Special Issue on Mobile Computing and Ubiquitous Networking for Smart Society

Guest editor, Akira Uchiyama (The University of Osaka) and Jaehoon Paul Jeong (Sungkyunkwan University)

Call for paper

Special Issue on Advanced Materials and Technologies for Sensor and Artificial- Intelligence-of-Things Applications (Selected Papers from ICASI 2026)

Guest editor, Sheng-Joue Young (National Yunlin University of Science and Technology)

Conference website

Call for paper

Special Issue on Innovations in Multimodal Sensing for Intelligent Devices, Systems, and Applications (submission closed)

Guest editor, Jiahui Yu (Research scientist, Zhejiang University), Kairu Li (Professor, Shenyang University of Technology), Yinfeng Fang (Professor, Hangzhou Dianzi University), Chin Wei Hong (Professor, Tokyo Metropolitan University), Zhiqiang Zhang (Professor, University of Leeds)

Call for paper

Special Issue on Multisource Sensors for Geographic Spatiotemporal Analysis and Social Sensing Technology Part 5

Guest editor, Prof. Bogang Yang (Beijing Institute of Surveying and Mapping) and Prof. Xiang Lei Liu (Beijing University of Civil Engineering and Architecture)

Special Issue on Advanced GeoAI for Smart Cities: Novel Data Modeling with Multi-source Sensor Data

Guest editor, Prof. Changfeng Jing (China University of Geosciences Beijing)

Call for paper

-

For more information of Special Issues (click here)

-

Special Issue on Materials, Devices, Circuits, and Analytical Methods for Various Sensors (Selected Papers from ICSEVEN 2025)

- Accepted papers (click here)

- Voltage Reflex and Equalization Charger for Series-connected Batteries

Cheng-Tao Tsai and Jia-Wei Lin

- Voltage Reflex and Equalization Charger for Series-connected Batteries

- Accepted papers (click here)

- Design and Development of a Fuzzy-logic-based Long-range Aquaculture System

Sheng-Tao Chen and Tai-I Chou

- Design and Development of a Fuzzy-logic-based Long-range Aquaculture System

Guest editor, Chien-Jung Huang (National University of Kaohsiung), Mu-Chun Wang (Minghsin University of Science and Technology), Shih-Hung Lin (Chung Shan Medical University), Ja-Hao Chen (Feng Chia University)

Conference website

Call for paper

Special Issue on Sensing and Data Analysis Technologies for Living Environment, Health Care, Production Management, and Engineering/Science Education Applications (2025)

Guest editor, Chien-Jung Huang (National University of Kaohsiung), Rey-Chue Hwang (I-Shou University), Ja-Hao Chen (Feng Chia University), Ba-Son Nguyen (Lac Hong University)

Call for paper

Special Issue on Advances in Sensors and Computational Intelligence for Industrial Applications

Guest editor, Chih-Hsien Hsia (National Ilan University)

Call for paper

Special Issue on AI-driven Sustainable Sensor Materials, Processes, and Circular Economy Applications

Guest editor, Shih-Chen Shi (National Cheng Kung University) and Tao-Hsing Chen (National Kaohsiung University of Science and Technology)

Call for paper

Special Issue on Intelligent Sensing and AI-driven Optimization for Sustainable Smart Manufacturing

Guest editor, Cheng-Chi Wang (National Sun Yat-sen University)

Call for paper

- Accepted papers (click here)

Copyright(C) MYU K.K. All Rights Reserved.